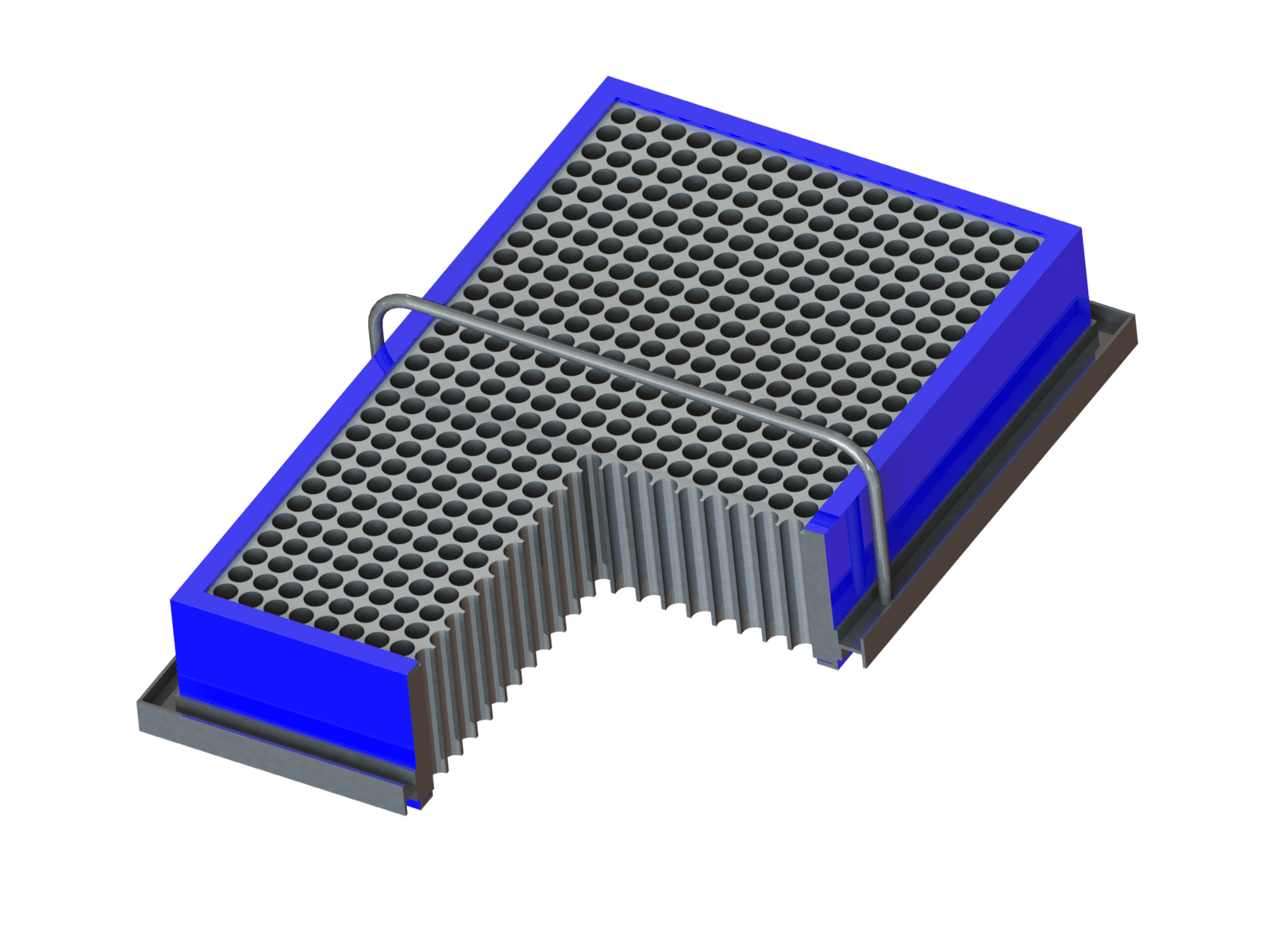

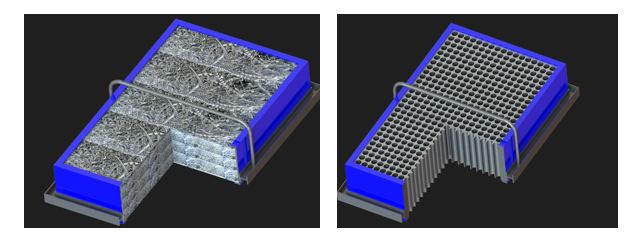

As a technology leader of enameled wire machines, we are constantly striving to improve our machines. For example, our new machines from year of manufacture 2019 have been equipped as standard with a honeycomb catalyst developed by MAG for the recirculation and after burning catalysts.

All our existing machines can be easily retrofitted with MAG´s new catalyst system.

A change/switch to a MAG Honeycomb recirculation catalysts makes a lot of sense: why it makes sense to switch to a MAG honeycomb recirculating catalyst make sense:

- Minimal washing/cleaning due to non-blocked laminar tube air flow No more time-consuming cleaning process required.

- Low energy consumption of the oven

- Higher plant efficiency

- work even at lowest oven temperatures and highest solvent loadings

- Stable baking zone temperatures

- Lower pollutant levels in the oven exhaust

Why a change to a MAG honeycomb post-combustion catalyst makes sense:

- No more time-consuming cleaning process required

- Additionally reduced pollutant values in the oven exhaust

For further information, please do not hesitate to contact the sales team!