Surface Technology

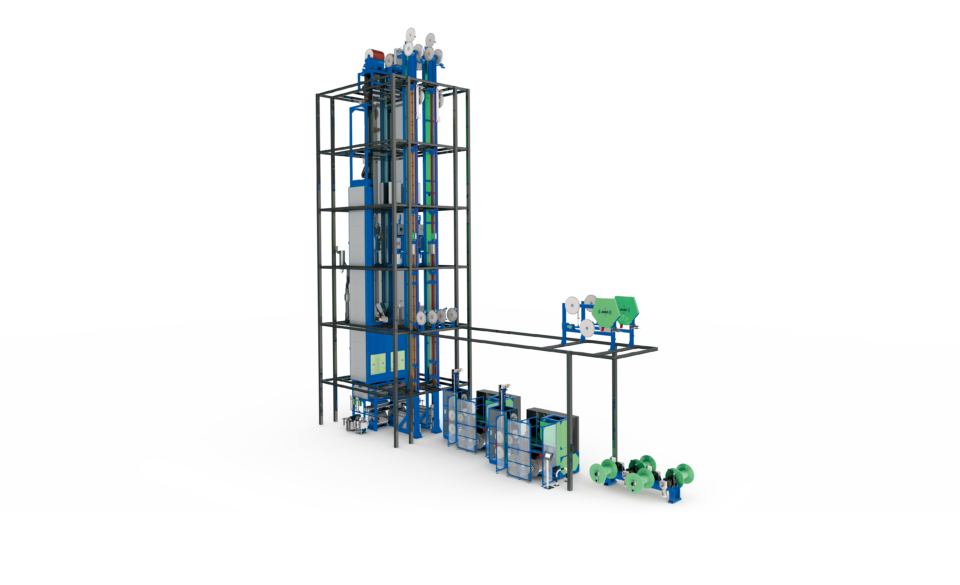

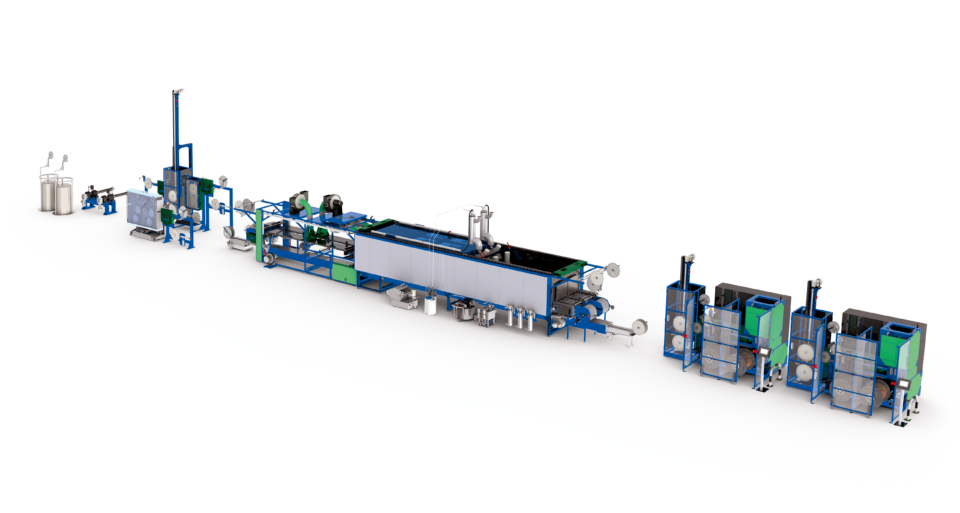

Surface Technology – Our Know-How for Your Success

Learning about surfaces is a natural side effect when you’re working in and optimizing enameled wire production – something we’ve been doing for over 70 years. We actively use the expertise we’ve gathered during this time for your benefit.

The surface of any metal has a unique structure, and efficiently applying a robust coating will require the appropriate level of expertise. In the 70 years since the foundation of MAG, we have acquired the necessary skills to do so.

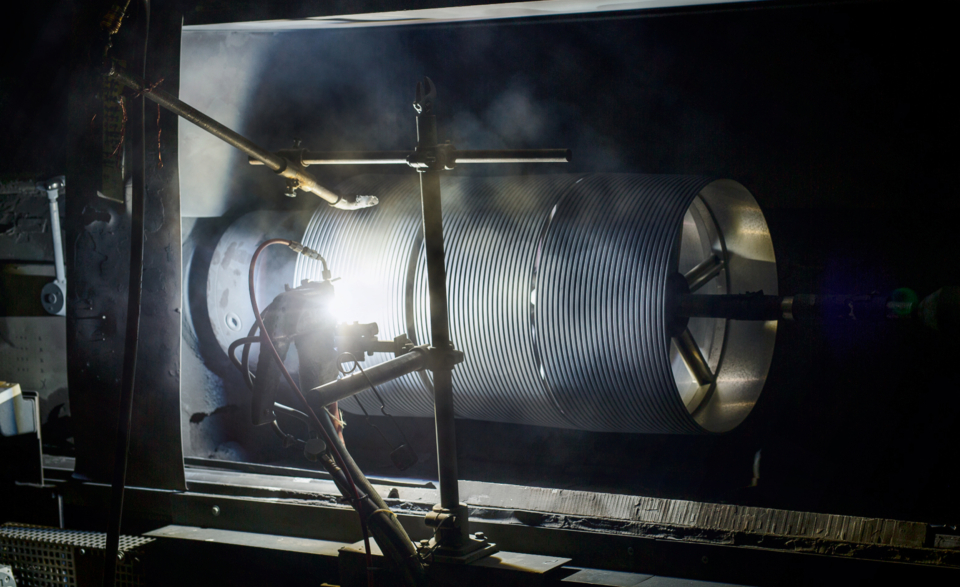

We coat any metallic material used in mechanical engineering (even hardened steel) through thermal spraying.

This coating process first melts the coating agent and then sprays it onto a surface through kinetic energy. Once the coating agent is on the surface, its particles interlock and form an even, protective layer with little porosity that bonds firmly to the surface. With this technique, we can apply wear coats with a thickness of up to 72 HCR to surfaces in a particularly delicate manner.

Depending on the requirements for your material, we distinguish between the following coatings:

-

Anti-Wear Coat

protection against abrasion, cavitation and particle erosion

-

Anti-Corrosion Coat

protection against atmospheric corrosio

-

Thermal Coat

protection against oxidation, gaseous corrosion, heat erosion

-

Coat for Bearing Layers

-

Electrical Isolating and Contact Layers

-

Special Layers/Coats

high-friction coating, adhesion layers for plastic surfaces for special usage

MAG also offers contract manufacturing for the following services:

-

Cylindrical Grinding

-

Turning

-

Milling

-

Balancing of Rotating Masses

-

Laser Cutting