Innovation

Our Research.

For You. And Our Planet.

Because only those with the courage to raise the bar will remain at the fore.

Our Research

Focus

Research and development is a fundamental part of our identity here at MAG. Currently, our research is focusing on automating, optimizing, and digitizing our machines’ production processes as well as making it easier for you to use our machines. In so doing, we ensure that our equipment will continue to produce enameled wire with the top-notch quality our customers have come to expect. After all, progress can never come at the expense of quality!

We Take

Innovation Seriously

We are a company that always strives to improve – all our processes and products are under constant scrutiny. Innovation isn’t just a buzzword for us: a third of our staff works in research and development, we run our very own technical center, and we reinvest about 11% of our earnings in development activities. Because this is the only way that our industry can lead the way into a sustainable future.

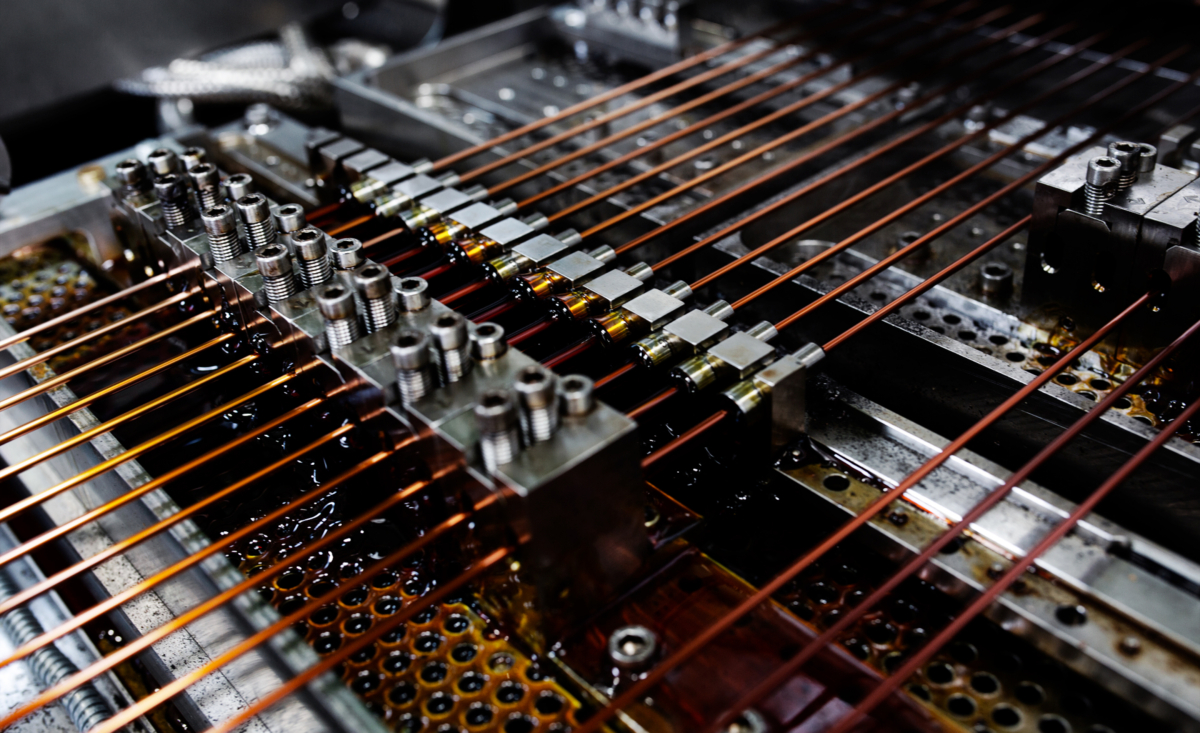

Our Very Own Research Center

In our headquarters close to Graz in Austria, we run our own MAG innovation center: this is where we present our machines, but more importantly it’s where we test and optimize them. While our employees fine-tune our machines, our customers can take a close look at our products.

Cooperation With Leading Universities and Companies

Without cooperation, there is no innovation – and that’s why we’re working together with leading universities and companies from the industry. For example, we’ve joined forces with the Institute of Fluid Mechanics and Heat Transfer at the Graz University of Technology in 2004. From the very beginning of this ongoing collaboration, we’ve worked together on research projects that combine established industry technology with cutting-edge innovation, thus creating the enameled wire machines of the future.

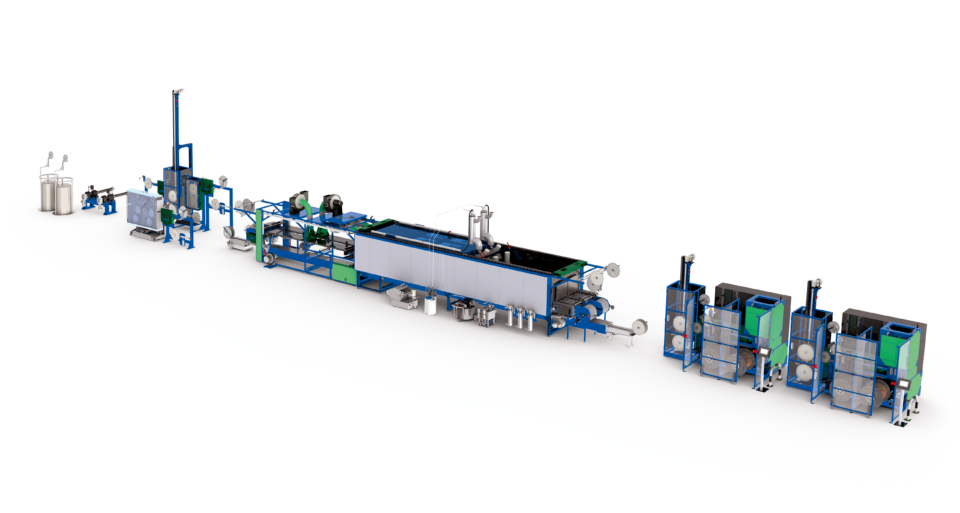

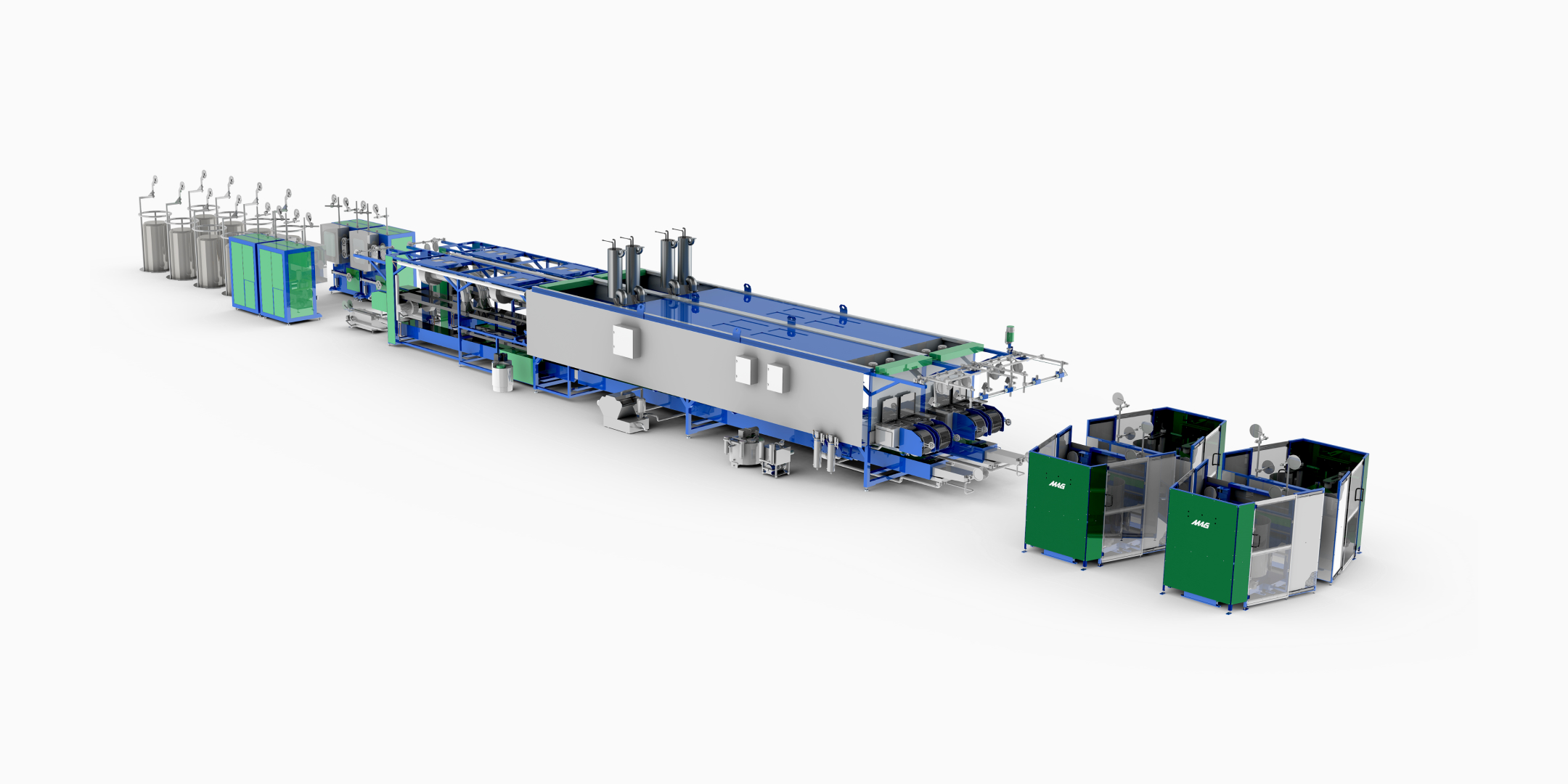

With Mozart Zero, MAG Is Boldly Leading the Way in Enameled Wire Production

Mozart Zero by MAG. Setting Industry Standards.

When the name says it all: our Mozart Zero technology brings art to the science of wire coating. Thanks to the oven’s optimized operation, additional heat is almost never necessary – if ever at all.

Where the production of enameled wire once required huge amounts of energy in order to heat up the oven and maintain an operating temperature of 700 °C, Mozart Zero has successfully cut energy consumption in half. Our R&D team found a way to reduce heat loss as much as possible, making the coating process more energy efficient than ever before.

The energy saved thanks to Mozart Zero is enough to power around 571 households for one year – you won’t find a better example for efficiency and resource conservation in this industry.