Rallying enrergie prices have taken a huge toll on magnet wire producers all over the world. In Europe, electric power prices have multiplied within a few weeks and remained on a very high level throughout 2022. Particularly in times like these, machines with significantly reduced energy consumption secure a huge competitive advantage and, therefore, are more and more in the focus of enameled wire producers.

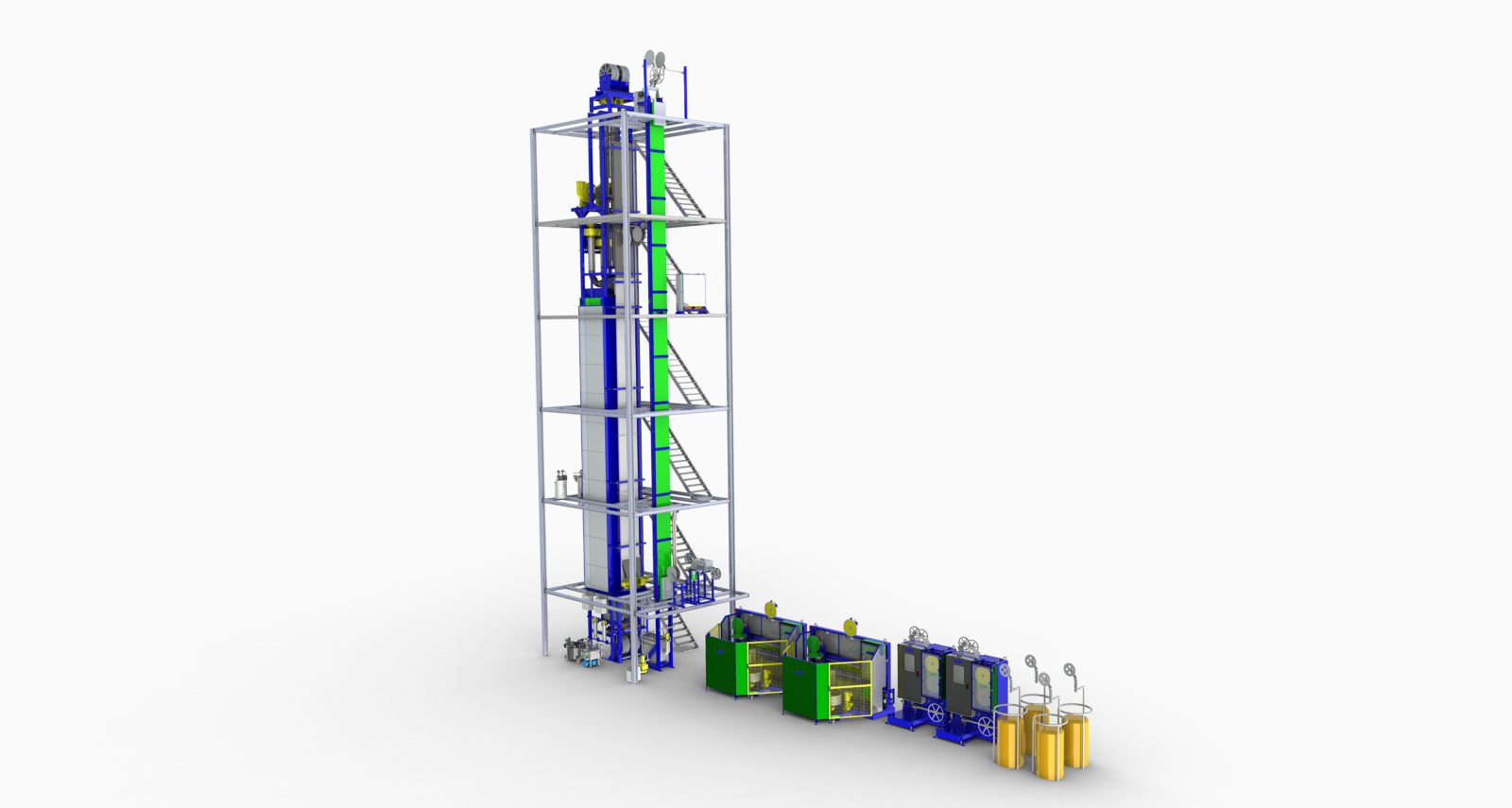

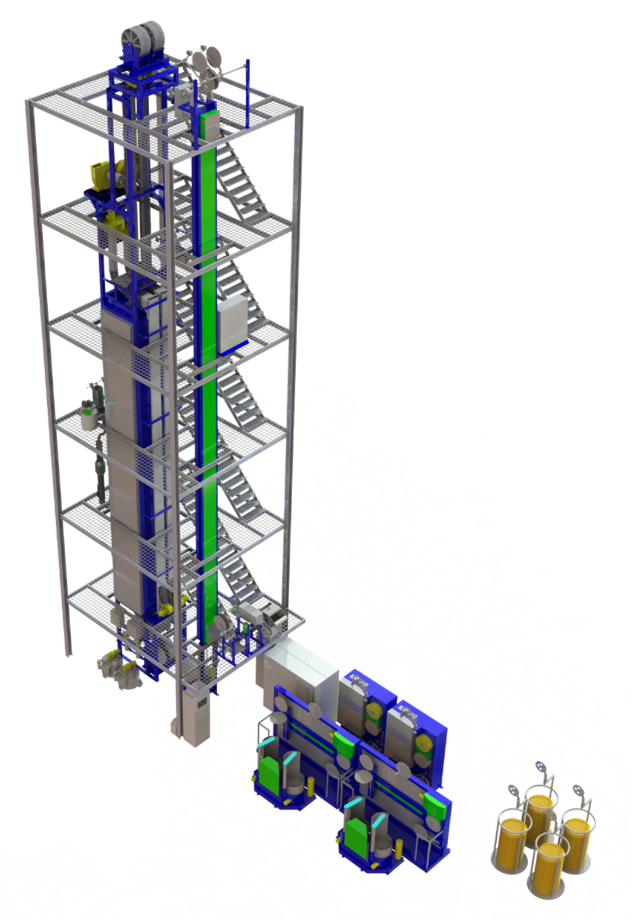

The production of energy-efficient magnet wire machines has been one of MAG’s core competencies for decades. The proven MAG Zero technology has now been fully implemented in the Mozart V7 machine. After numerous machine installations the Mozart Zero V7 was successfully validated in long-term operation. Enameled wire producers have confirmed up to 70% savings in energy costs achieved by Mozart Zero V7 compared to the previous model. In addition to outstanding energy data, the new Mozart Zero V7 offers an extremely wide dimensional range. Copper wires can be coated within a diameter range of 1.0 – 4.0 mm and aluminum wires within a range of 1.7 – 5.0 mm. Besides the particularly low energy consumption and a wide range of applications, the new Mozart Zero V7 concept is characterized by a a constant product quality enabled by a fully automatic process control system.

With high energy costs, it is worth comparing existing machines with new and more efficient technological equipment. The savings in energy costs alone can justify a new investment in highly efficient Mozart Zero V7 machines. We will be pleased to assist in the evaluation of existing and new equipment.